A team of scientists and developers from both the University of California, Santa Barbara, and the Lawrence Livermore National Laboratory (LLNL) has put together an impressive resin 3D printer that is able to create more than one material from the same resin. Even more exciting is that one of those materials is dissolvable, making it an ideal option for printing supports in place.

In the world of 3D printing, there are two types of printers leading the way: fused deposition modeling (FDM) and resin printers. FDM printers are the ones you see squeezing filament out of an extruder onto a print bed. Resin printers rely on precise light exposure to build layers in a vat of liquid resin. It's through this technology that the team was able to hone in on specific wavelengths to generate the differing materials.

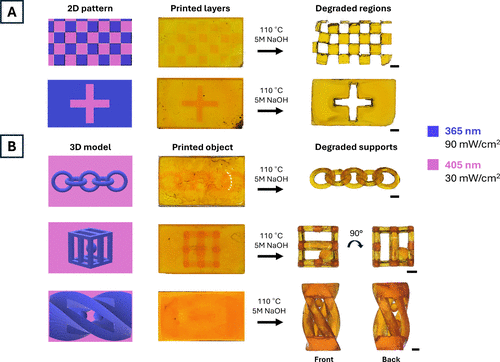

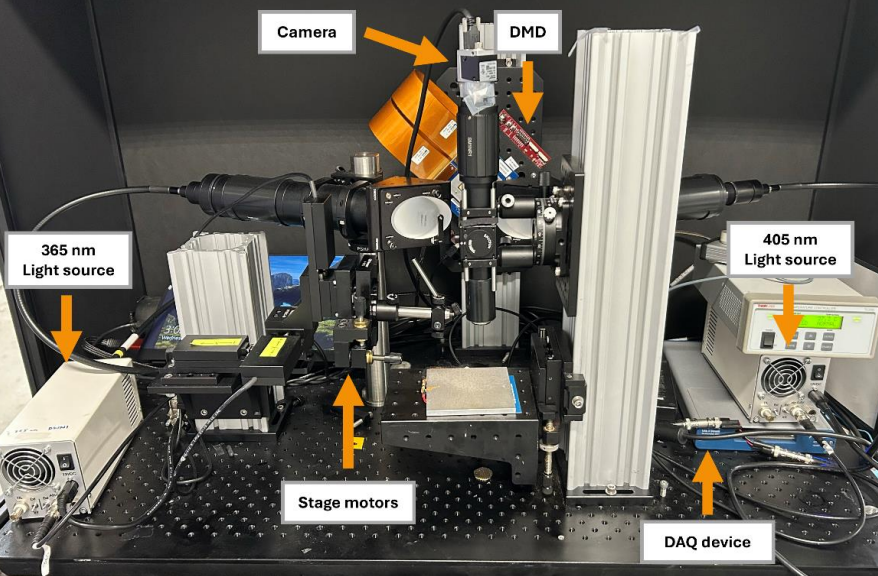

According to the team, the resin is comprised mostly of acrylate monomers and epoxy, which is crucial. The printer is designed to use two different types of light beams when printing. One is ultraviolet, while the other is just visible light. Focusing these lights in tandem allows the printer to develop multiple materials from a single resin.

When the UV light is focused into the resin, solid permanent structures are formed. This is used for the main object you're printing. When visible light hits the same resin, a solid material is formed that will dissolve in 15 minutes when placed in a lye solution. This is what makes the material ideal for printing supports.

To demonstrate the system in action, the team has created a handful of objects that would be impossible to print otherwise. For example, they managed to print a ball suspended in a cage that moves about freely once the support material is dissolved. They also created a chain of interlocked rings and a checkerboard pattern.

If you're new to 3D printing or are looking to upgrade your current printer, check out our list of best 3D printers to see which ones we personally recommend. This also gives you an idea of what's leading the market. Unfortunately, you won't find any resin printers capable of creating two materials from a single resin but in the meantime, we can at least appreciate the work this team has done so far to innovate how we handle resin printing.

Follow Tom's Hardware on Google News to get our up-to-date news, analysis, and reviews in your feeds. Make sure to click the Follow button.

Stay On the Cutting Edge: Get the Tom's Hardware Newsletter

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Ash Hill is a contributing writer for Tom's Hardware with a wealth of experience in the hobby electronics, 3D printing and PCs. She manages the Pi projects of the month and much of our daily Raspberry Pi reporting while also finding the best coupons and deals on all tech.

-

John Nemesh Pretty damn interesting! I wonder how much the printer, and more importantly how much the resin will be. Hopefully it doesn't take a long time to hit the market!Reply -

chemistu Interesting. But boiling your prints up in 5 Molar sodium hydroxide at 110C for an unspecified length of time (the chemist remaining in me is suggesting a few hours) seems a little extreme for it to catch on for home useReply