AI can track 3D printed parts back to specific machine that made them

Could it be used to find the origin of 3D-printed guns?

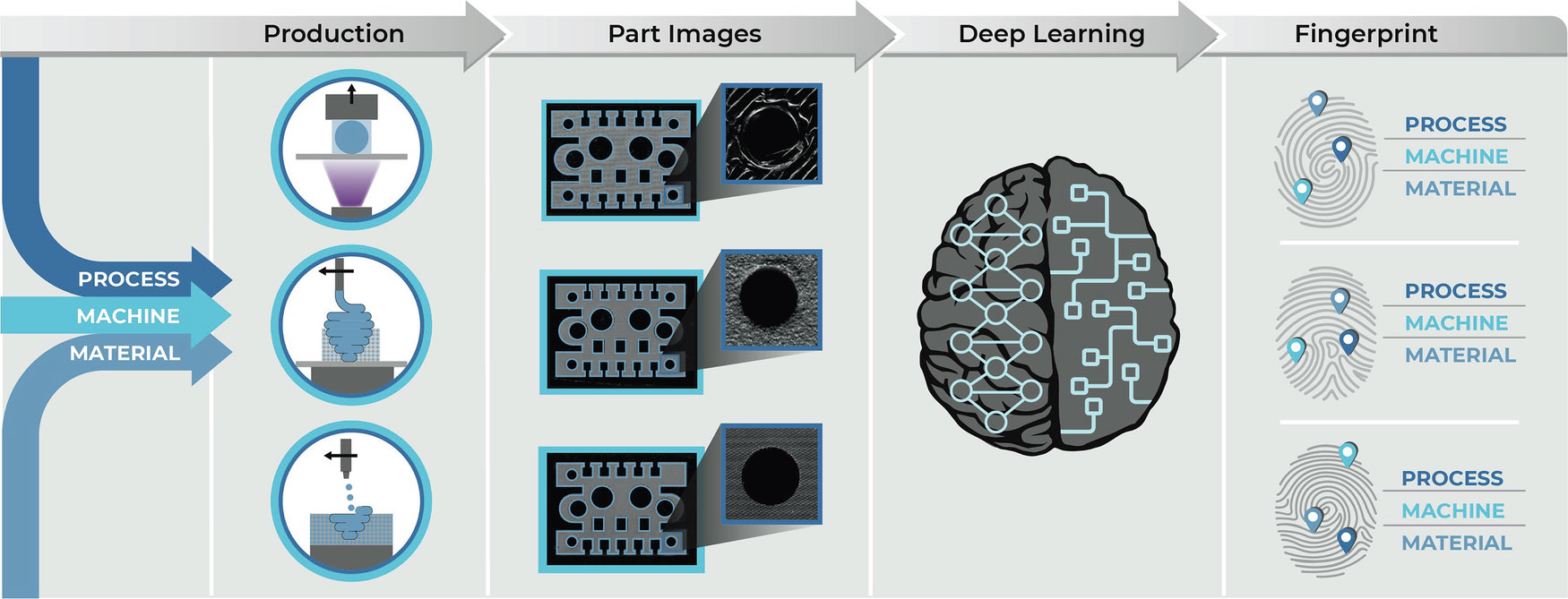

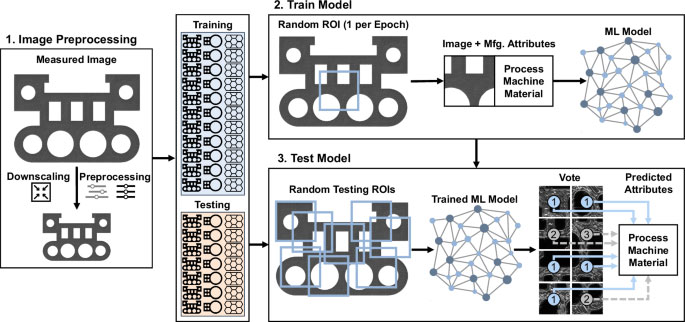

Researchers have developed an AI-driven system which can pinpoint “the specific machine” following an inspection of the 3D printed parts it has produced. A Grainger College of Engineering team from the University of Illinois Urbana-Champaign say that the system could be used for managing supply chains, “detecting early problems and verifying that suppliers are following agreed upon processes.”

However, talk of the “hidden fingerprints” of 3D printers have got this Sherlock, Columbo, Monk, and Fargo fan more interested in the criminal investigatory implications of the new AI.

Implications for manufacturing, quality, and trust

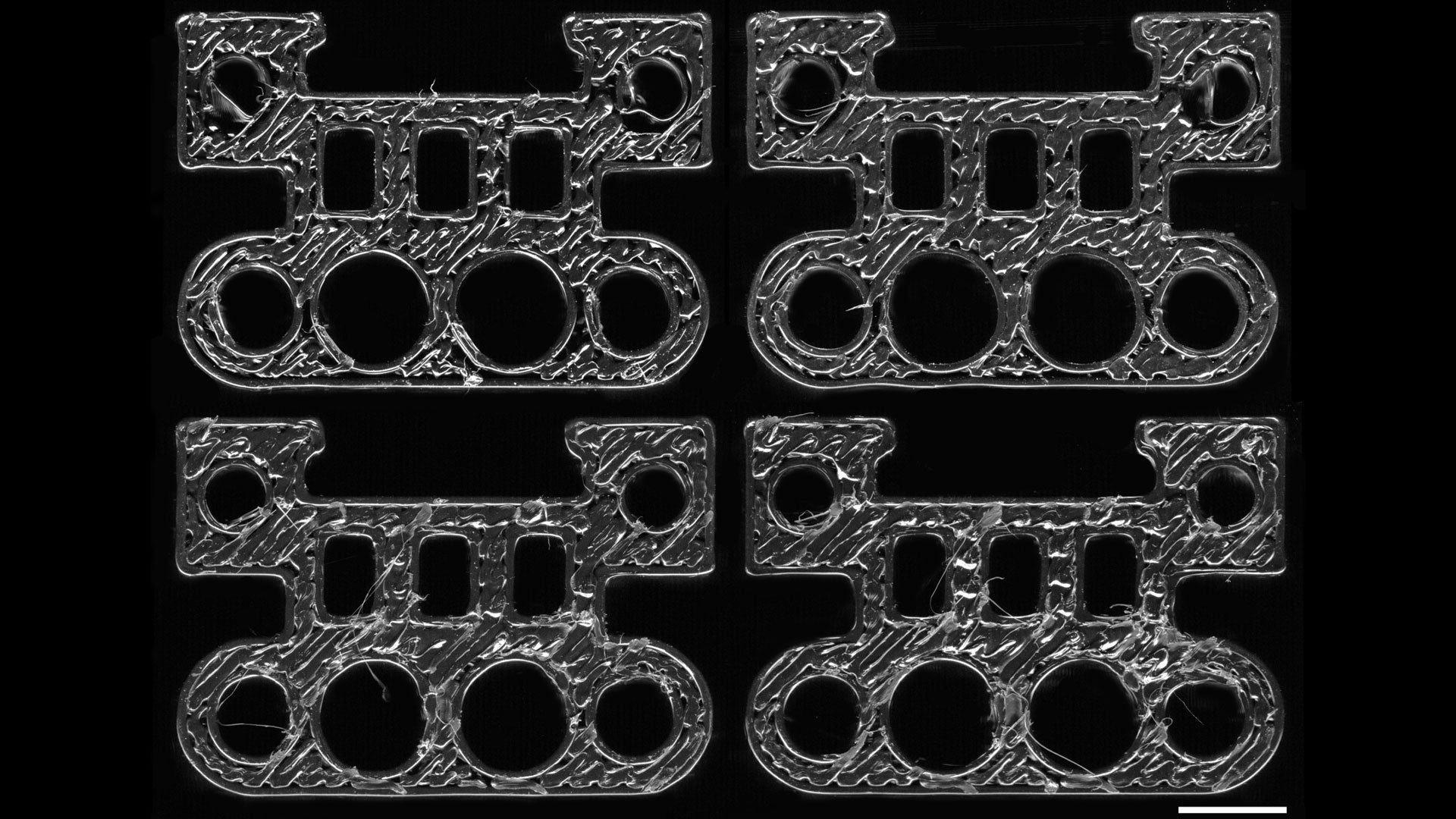

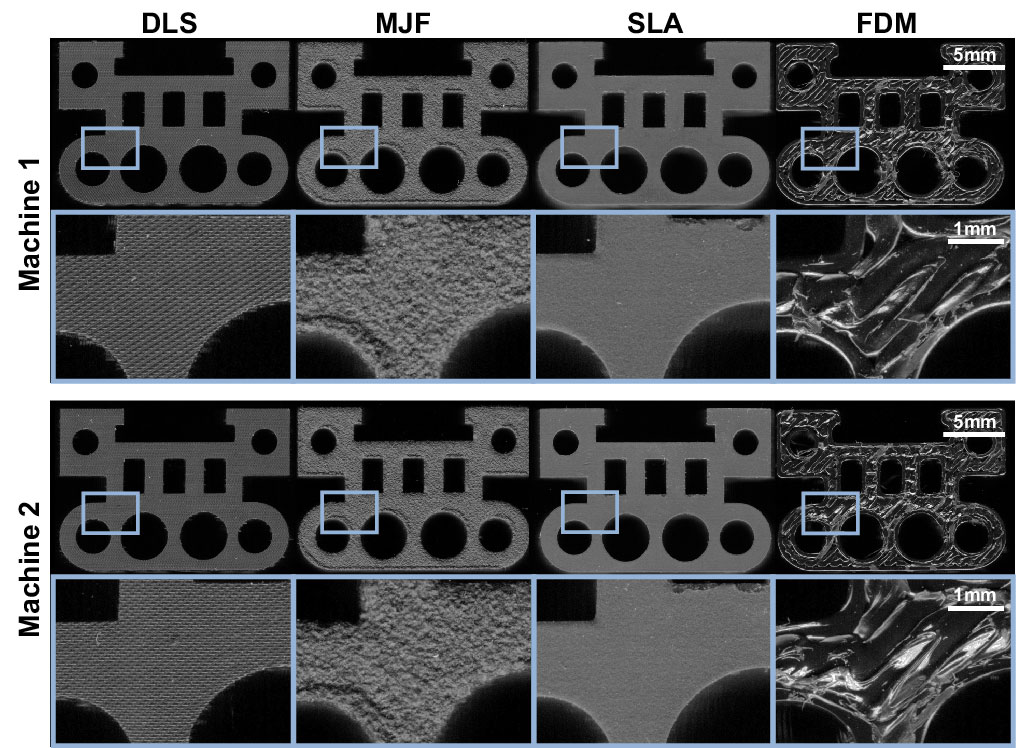

Only a photograph of a part printed by a certain 3D printer is needed to verify its “unique signature... or fingerprint” says the Grainger blog. “We are still amazed that this works: we can print the same part design on two identical machines – same model, same process settings, same material – and each machine leaves a unique fingerprint that the AI model can trace back to the machine,” said Bill King, a professor of mechanical science and engineering, and the research project leader. “It’s possible to determine exactly where and how something was made. You don’t have to take your supplier’s word on anything.”

The researchers looked most closely at the (major) implications for supplier management and quality control. They described how this was important to 3D printer vendors to ensure users “adhere to a specific set of machines, processes, and factory procedures” to deliver the expected quality levels throughout the printing / production process.

In tests, smartphone photographs of 9,192 parts made on 21 3D printing machines from six companies, and with four different fabrication processes, could be fingerprinted “with 98% accuracy from just 1 square millimeter of the part’s surface.” It would be interesting to see how much more accurate the Ai could be, given a larger area to anaylze.

Beware of using your 3D printer for 'illicit goods'

Despite what sounds like a rather narrow focus on 3D printers used in factory production environments, the AI can work its magic on a far broader pool of devices.

“These manufacturing fingerprints have been hiding in plain sight,” King said. “There are thousands of 3D printers in the world, and tens of millions of 3D printed parts used in airplanes, automobiles, medical devices, consumer products, and a host of other applications. Each one of these parts has a unique signature that can be detected using AI.” We assume King's assertion includes all the printers listed in the regularly updated Tom's Hardware's best 3D printers article.

Stay On the Cutting Edge: Get the Tom's Hardware Newsletter

Get Tom's Hardware's best news and in-depth reviews, straight to your inbox.

Beyond its touted use for supply chain management, the researchers say the tech could be applied to “track the origins of illicit goods.” Other than that, they don’t discuss any implications for criminal investigations. However, we’d like to see the technology used to trace the origin of a 3D printed gun discovered at a crime scene, for example.

Mark Tyson is a news editor at Tom's Hardware. He enjoys covering the full breadth of PC tech; from business and semiconductor design to products approaching the edge of reason.

-

hotaru251 headline sounds cool, but actual context is full of holes.Reply

given how people mod their printers a lot of the "default" that would be in results of this would make it have a much greater error rate. -

Rob1C Seems legit, but it took 400 days of training: https://github.com/wpklab/fingerprintingReply

As for vapor smoothing, 2D ink printers can be found the same way if used for counterfeiting, much as filing the serial numbers off of a gun may not avoid proper forensic techniques:

ld4hJmxP9Zk -

Velloska How much does the wear of parts alter the signature of the printer? What about using different slicers or materials for that printer? I feel there are a lot of things that could be changed both physically and within your gcode to change the fingerprint of your printer that would make it next to impossible to trace someone making illicit parts that doesn't want to be found.Reply -

BFG-9000 Reply

Both laser and inkjet printers have firmware to print microscopic markers onto every page, known as tracking dots or machine identification codes. If 3D printer firmware in the future is required to embed serial numbers or other identification into the prints in the same way, then AI would not be needed, only a microscope.Rob1C said:2D ink printers can be found the same way

Similarly, explosives may contain taggants to identify the manufacturer and type of explosive, + while the Clinton administration attempted to require them in gunpowder, it did not prove to be feasible to do so. Not that that always helps--California passed a law to require microstamping of the gun's serial number onto the cartridge at the moment of firing by Jan 1, 2028 despite a similar proposal being withdrawn a decade before because it was considered technically impossible to reliably do so. This is seen as a backdoor way to ban all weapons because none can meet the standard.

Be glad that 3D printers are still available despite the attempts to restrict the availability of files for them so far being futile.

In the United States it is perfectly legal to make your own firearm the old fashioned way with a lathe + other machine tools, and no serial number is required. These cannot be sold or moved across state lines (or the Interstate Commerce Clause allows the Feds to regulate). The fear with 3D printed guns is they are too easy to make, in much the same way that Twitter makes it all too easy to publish your thoughts worldwide in ways the founders never considered, therefore they "must have" meant to allow censoring that. If rights are supposed to be difficult to exercise, then requiring a poll tax and being a landowner to vote must be OK too. -

Wildbillnye Reply

exactly, how much is doubling retraction from 1mm to 2mm and increasing linear speed 20% going to change a printers "signature"? nozzle swap? tighten belts? hardly going to be useful forensically.Velloska said:How much does the wear of parts alter the signature of the printer? What about using different slicers or materials for that printer? I feel there are a lot of things that could be changed both physically and within your gcode to change the fingerprint of your printer that would make it next to impossible to trace someone making illicit parts that doesn't want to be found. -

Rob1C Reply

... and some money has a EURion Constellation.BFG-9000 said:Both laser and inkjet printers have firmware to print microscopic markers onto every page, known as tracking dots or machine identification codes. If 3D printer firmware in the future is required to embed serial numbers or other identification into the prints in the same way, then AI would not be needed, only a microscope.

But you can download firmware and reflash your printer/copier allowing it to print anything without markers or outputting a warning page (Canon) that says it suspects that you tried to copy currency; and it leaves a note for the service technician.

Thus falling back on what I said. -

BFG-9000 Constellation is a way to both help tell if a note is genuine and so copiers (or software like Photoshop) can determine if the user is attempting to copy things like currency or edit title documents, but probably doesn't have much to do with forensics to tell authorities what printer printed them. They know what printers used them because they own some of them, at the mint! And presumably any counterfeiter would not need to know what the symbols mean but only try to duplicate them as faithfully as possible.Reply

The tracking dots are for that, and explains the continuing trope of using pasted-together cut-out letters from newspapers and magazines to write ransom notes and such on TV (in the olden days they would use slight defects in typewriter hammers to identify if a document was typed on a particular typewriter, or of course handwriting analysis). As it happens I have working printers from the 1980s which are too old to include such a system but alas, have no reason to print such notes!

Over here we don't have anything standard like Constellation on checks (only a VOID pantograph message that appears if copied), but if you want to print checks yourself you have to use either MICR magnetic toner or preprinted pages of checks already printed with that. I don't think that has anything to do with forgery/counterfeiting though but only to make the checks more machine-readable, since there are also specified MICR fonts.

Even our currency only features traditional anti-forgery techniques such as fine detail, raised ink from special presses (I heard North Korea bought the same intaglio presses that we use, specifically to counterfeit US currency and it may be the only thing keeping their economy afloat) and now special paper with embedded red and blue lint, a single clear thread and for $100 bills a blue 3D plastic ribbon with holograms printed on it kind of like on the Euro. They also went to color-shifting ink on some areas, also used on the Euro. The lint sounds dumb but apparently it's really difficult to print a realistic image that resembles them embedded at varying depths so that may be considered effective enough without having to force every printer and software maker to embed security features.